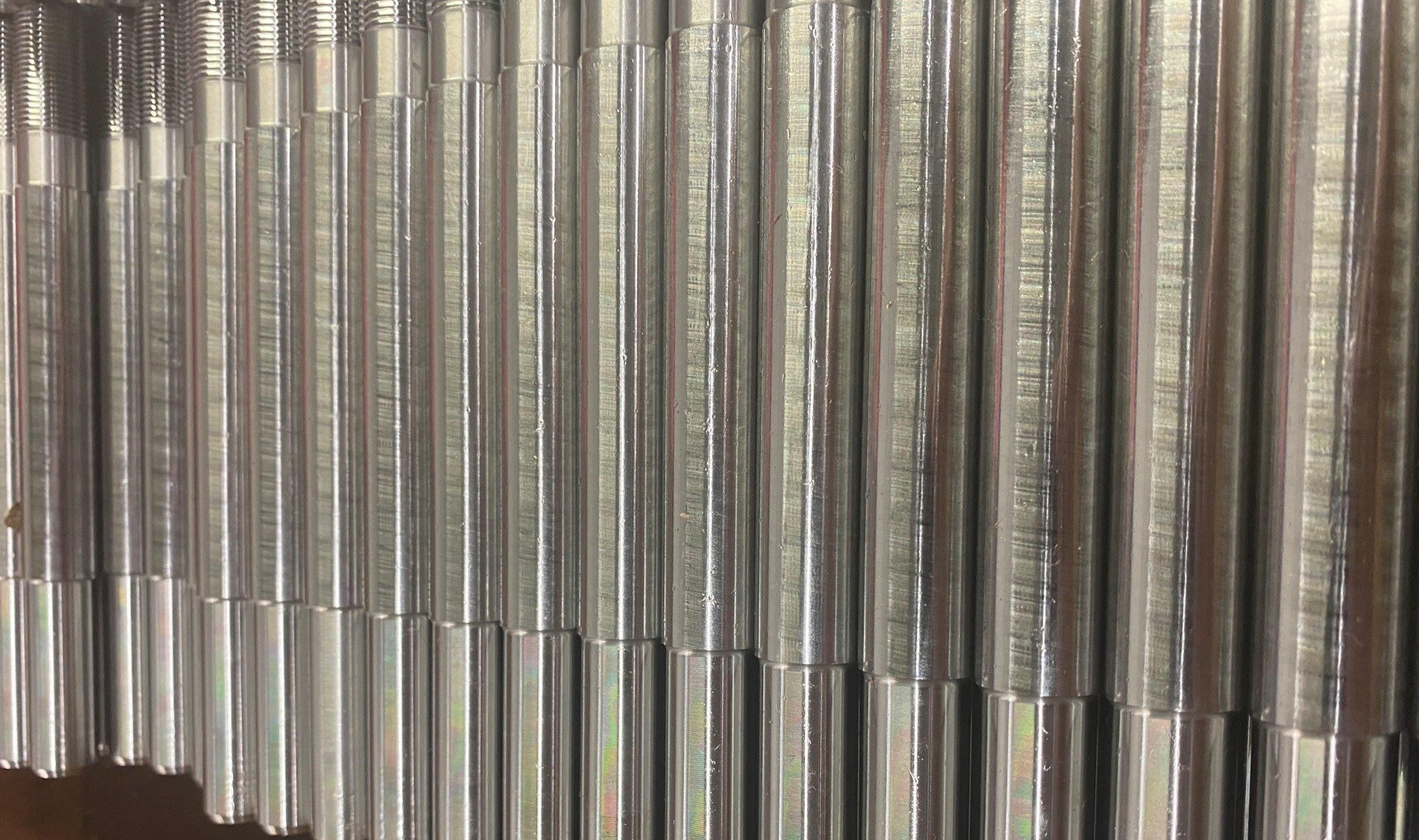

At Rolled Threads Unlimited, one aspect of our business is rolling threads onto customer prepared parts. In those instances, it is imperative that the parts are provided to us by the customer with the correct blank diameter on the area to be threaded. Pre-roll thread blank diameters must be precision turned or ground to produce a precision thread.

We require our customers to contact us prior to machining their parts in preparation for thread rolling to ensure a proper rolled thread to meet print specifications. While thread size charts are widely available in books and online, the following factors (plus several others) must be considered when determining the exact pitch diameter within that range:

- Thread Size/Pitch – Threads with the same major diameter will have different blank sizes based on the thread pitch.

- Material Type – Different material types may require a tighter turn or grind. Some blank sizes may require only a +/-.0010 range while others may require a tighter +/-.0005.

- Class Fit – A blank size would differ on a unified thread depending if the thread requires a 1A, 2A or 3A fit. The same logic would apply for different class fits for metric, acme, and trapezoidal threads.

- Plating – It is important to account for whether parts are plated or not, and what the plating thickness will be.