When talking about difficult work, Vince Lombardi once said, “The price of success is hard work, dedication to the job at hand, and the determination that whether we win or lose, we have applied the best of ourselves to the task at hand.”

Well, leading change in manufacturing policies and procedures is hard. It takes time, effort, and buy-in from employees. For several years, Rolled Threads Unlimited has increased its focus on lean management, continuously evaluating manufacturing and management practices and identifying areas of improvement that increase efficiency, reliability, employee engagement, and ultimately, the bottom line.

While evaluating all areas of our business, the smallest changes can lead to tremendous savings in time and money. For example, early in 2020, a simple change in the type and amount of tape used to package customer parts drastically cut the labor and cost required to effectively protect customer parts. This seemingly tiny change has allowed our packing/shipping department to keep pace with our continued growth with the same number of employees.

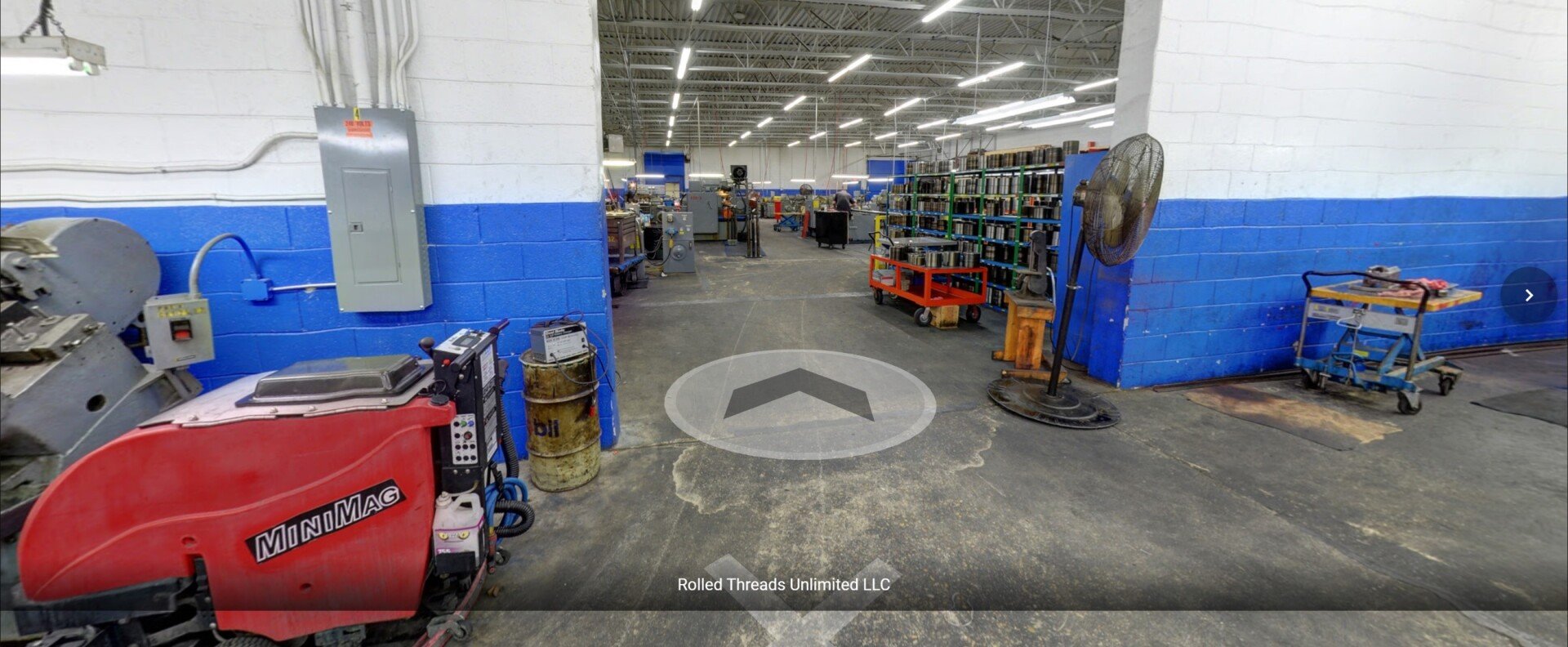

This article describes how lean management can even be used as a marketing tool for your company. Part of this article discusses virtual tours; be sure to check out our very own virtual tour of our facility.