Developed in the 1890s, Acme threads were designed to replace square threads and a variety of other formed threads to produce traversing motions on machines, tools, and for heavy load work. Acme threads were an advantage over square threads, which had straight-sided flanks and were difficult to manufacture with available cutter technology. While the square form was relatively efficient for the purposes required, it was inherently weak at the base of the thread due to the sharp 90-degree angle of the flank.

There are three different types of Acme screw threads: General Purpose, STUB-Acme and Centralizing. General Purpose Acme threads are designed to ensure interchangeability with three classes of fit and condense the amount of inventory of both tools and gauges. STUB-Acme threads have been truncated, shortened or “stubbed” for use in smaller spaces with many authorized varieties. Centralizing Acme threads are the same as General Purpose—the difference being that they have a restricted clearance at the major diameter of both the internal and external screws that prevent wedging on the flanks.

There are three different types of Acme screw threads: General Purpose, STUB-Acme and Centralizing. General Purpose Acme threads are designed to ensure interchangeability with three classes of fit and condense the amount of inventory of both tools and gauges. STUB-Acme threads have been truncated, shortened or “stubbed” for use in smaller spaces with many authorized varieties. Centralizing Acme threads are the same as General Purpose—the difference being that they have a restricted clearance at the major diameter of both the internal and external screws that prevent wedging on the flanks.

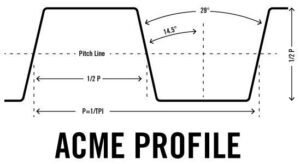

All three varieties of acme threads use a 29-degree angle, which makes it broader, stronger and more square than standard V-shaped threads. They are often used for jack screws, lead screws, CNC systems and many other applications. It is also often needed in industrial applications that require heavy torque and power transmission such as lathes, milling machines and presses. Acme thread is the best choice for power transmission and carrying loads. Their thickness and width also help them perform better in environments with dirt and debris.

Acme threads are used much more commonly in the United States while the closely related trapezoidal thread form (30-degree angle) is preferred in Europe. Be sure to visit our blog where we dive into the differences between acme and trapezoidal threads.

Overall, acme screws have much better wear properties, load capabilities, and tolerances than standard threaded rod.

Here at Rolled Threads Unlimited, we have incredible capability within the Acme Form:

- 2 through 32 Pitch

- .0625” through 7.00” Diameter

- Profile: General Purpose, Centralized, Stub

- Specifications: ANSI/ASME B1.5, ASME/ANSI B1.8

- 2C, 2G, 3C, 3G: Multiple leads available. Most common tooling on hand.

If you’re interested in learning more about our Acme Thread capabilities, please don’t hesitate to contact us.