During World War II, problems with lack of interchangeability among parts plagued America, Canada, and Britain. After the war, transportation and trade were becoming more fluid, manufacturing was taking a global stage, and the transfer of knowledge and best practices was increasing. As a result, the three aforementioned countries agreed to unify inch-based thread standards, and in 1949, the Unified Thread Standard (UTS) was adopted, now commonly referred to as the UN thread series.

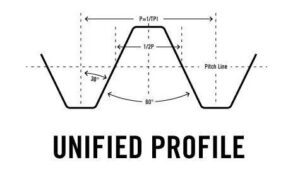

UN threads consist of a symmetric V-shaped thread. They have the same 60° profile as ISO metric screw threads, but the characteristic dimensions of each UN thread—outer diameter and pitch—are noted as inch fractions in lieu of round millimeter values.

UN threads consist of a symmetric V-shaped thread. They have the same 60° profile as ISO metric screw threads, but the characteristic dimensions of each UN thread—outer diameter and pitch—are noted as inch fractions in lieu of round millimeter values.

A standard UN designation starts with a number indicating the major diameter of a thread, followed by a number that signifies the pitch, measured in threads per inch (TPI). Succeeding this number pair is an indication of the thread’s coarseness: Unified Coarse Thread (UNC), Unified Fine Thread (UNF), Unified Extra Fine Thread (UNEF), or Unified Constant (UN). Rolled Threads Unlimited produces unified threaded bars and fasteners in all of these.

At Rolled Threads Unlimited, our rolling capabilities in the Unified thread form consist of:

- Thread pitches ranging from 4 threads per inch to 100 threads per inch

- Mill or custom bar lengths up to 40 feet

- In-feed and through-feed applications from more than 1300 sets of dies

- ASME B1.1 and SAE AS8879 specifications

The unified thread form is also seen in UNJ threads; however, this profile has a larger root radius, thus increasing the minor diameters of the thread. As a result, UNJ threads are stronger and help reduce stress concentration.

If you would like to discuss unified threads—or any other thread form offered by Rolled Threads Unlimited—please reach out to us today.