Rolled Threads Unlimited takes pride in providing an extensive range of threaded products, from studs, lead screws, and bolts to specialty fasteners, threaded bars, and more. There are three general thread rolling approaches we use at Rolled Threads, thru-feed rolling, infeed rolling, and the combined infeed/thru-feed rolling.

Infeed setups can consist of two parallel dies that are rotated at the same speed and in the same direction. There is minimal axial movement between the dies and the workpiece throughout the rolling cycle. As the length of thread that can be rolled is limited by the die’s width, infeed thread rolling is most often used for short threaded lengths and shouldered or headed parts like bolts and double end studs. See an example here.

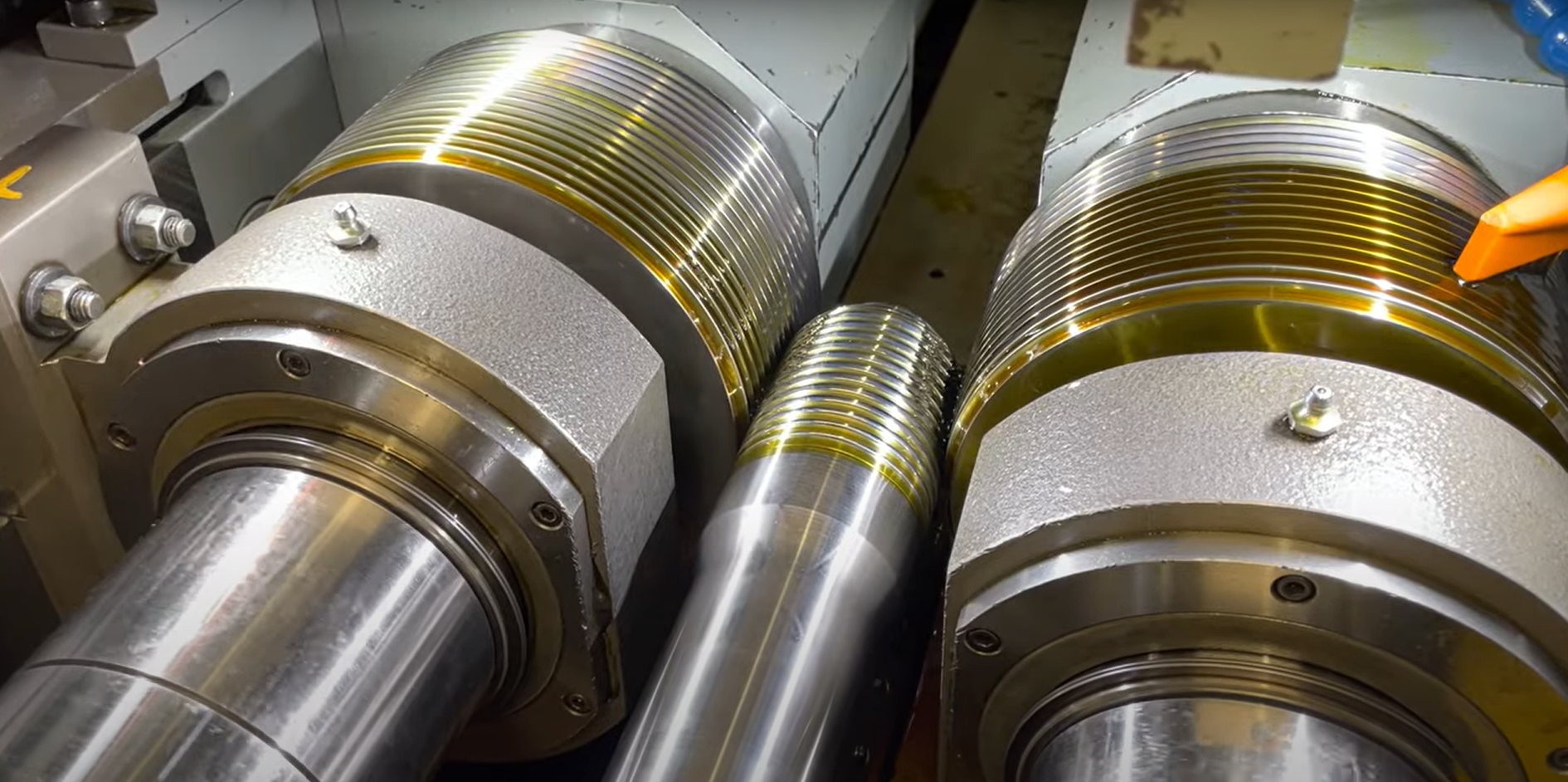

The thru-feed process also uses parallel dies that rotate at the same speed and direction moving the blank axially entering the dies from one side and leaving the dies from the other side, being threaded all along. Thru-feed rolling is used to roll threads that exceed the maximum width of the dies, as well as for continuous rolling of long threaded bars. On highly coarse threads, more than one pass may be required to form the thread to full depth. See an example here.

In-feed and thru-feed operations can also be combined into a two-step procedure. This procedure is used when the specific required thread length exceeds the width of infeed dies and incomplete threads are not acceptable beyond that length. See an example here

We would welcome the opportunity to share more about our thread rolling processes or answer any questions—reach out to learn more.