Proper Packaging is Key to Quality Assurance

Customers often choose rolled threaded products for their added thread strength and smooth surface finish. In order to maintain these attributes, special consideration must be given to proper packaging so that these parts arrive to the customer without any damage from shipping and handling.

Here at Rolled Threads Unlimited, we take proper packaging of our customer’s parts seriously. Here are some of the ways our customers have their parts shipped:

Boxing

- Wood Boxes and Crates – Most of our 6’-24’ rods are sent for shipping in wood boxes. The wood boxes protect against jostling and help maintain straightness of the bars. Large diameter individual pieces are often packed in custom built crates.

- Cardboard – Smaller studs are often secured in corrugated carboard boxes filled tightly with paper and layered with cardboard dividers to avoid thread nicking.

- Skidboxing – These are similar to cardboard boxes, but for larger and heavier parts. The boxes are connected directly to wood pallets for ease of transport and storage.

Thread Protection

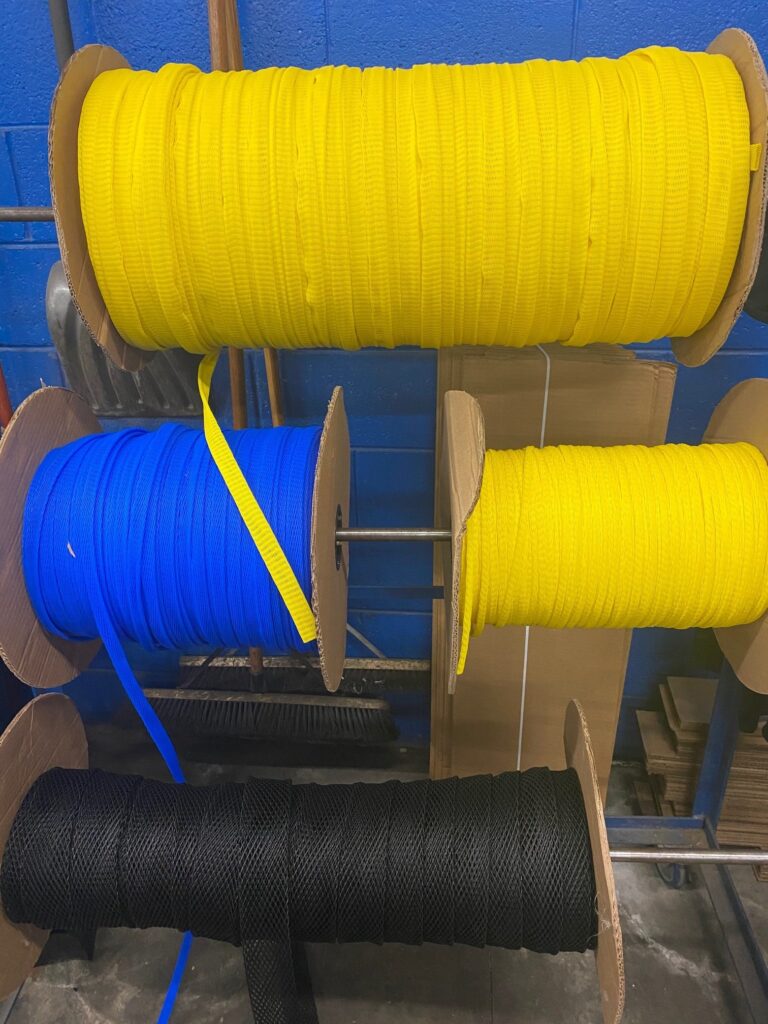

- Sleeving – Whether it be clear plastic or nylon mesh, individual part sleeving can add an additional level of protection at a low cost.

- Tubing – Heavy duty cardboard tubes can be used both for threaded rods up to 12’ as well as individual parts.

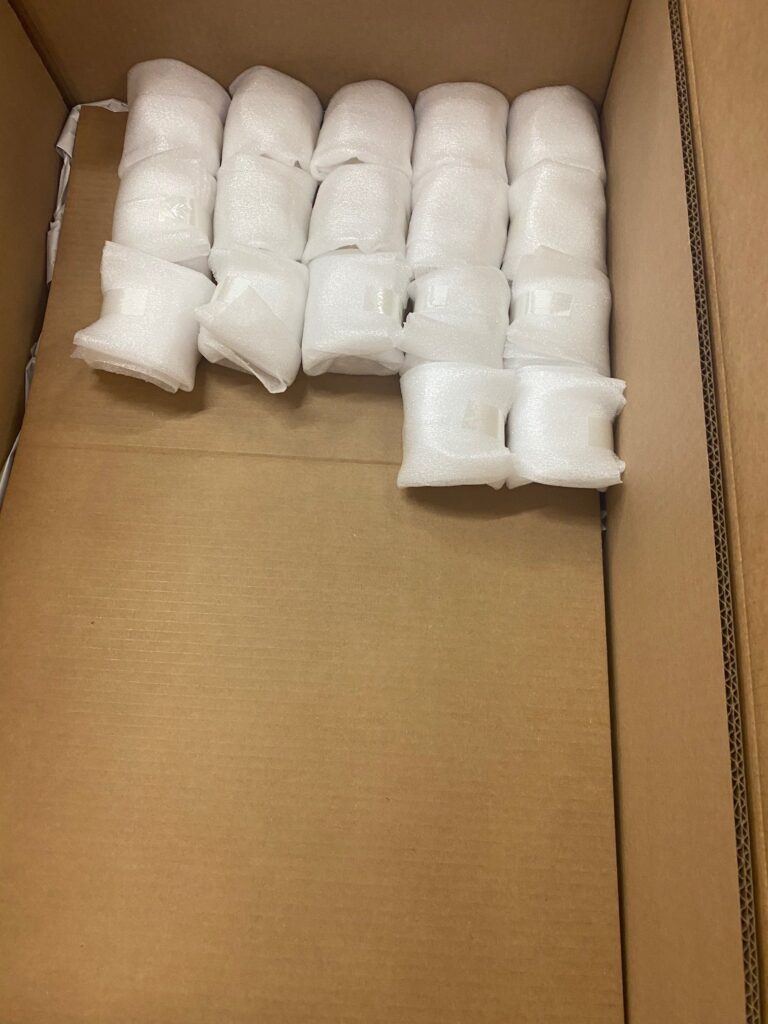

- Foam/Bubble Wrap – Parts can be individually wrapped in foam or bubble wrap for even more protection.

Corrosion Protection

- Parts that aren’t plated, and therefore, susceptible to corrosion over the long term, can be protected through rust preventative spray and or rust inhibiting paper.

For more on our packaging program, contact us at 262-547-6160 or [email protected].